Manufacturing Facility

VMC – HAAS VF2

Details :

- » Vertical Machining Center;

- » 30" x 16" x 20" (762 x 406 x 508 mm),

- » 40 taper,

- » 30 HP (22.4 kW) vector drive,

- » 8100 rpm,

- » inline direct-drive,

- » 20-station carousel tool changer,

- » 1000 IPM (25.4 m/min) rapids,

- » power-failure detection module,

- » 1 GB program memory,

- » 15" color LCD monitor,

- » USB port, memory lock key switch,

- » Rigid tapping and 55-gallon (208 liter) flood coolant system.

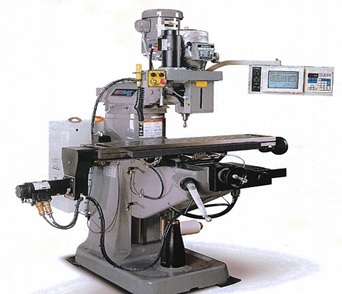

BFW – Surya VF30

Details :

- » Table size (clamping area)mm x mm315 x 1,060

- » Auto tool clamp –de clamp

- » Counterweight for vertical milling head to avoid drop during power failure

- » Brake motor for vertical axis

- » LM guide ways and ball-screws for all axes

- » Centralized oil lubrication for guide ways and ball-screws

- » Metallic covers and telescopic covers for guide way protection

- » Machine lamp

- » Table guards

CNC 200 – SANDS Precision

Details :

- » Chuck Dia. 250mm

- » Max. Turning Dia. 400mm

- » Max. Turning Length 500mm

- » 8 Station bi-directional turret

- » Hydraulic chuck and actuator

- » Hydraulic tail stock

- » Hydraulic powerpack

- » A C spindle motor

- » AC servo axes motors

- » Precision ball screws

- » Precision linear motion guideways

- » Coolant tank with rear chip tray

- » Isolation transformer

- » Machine lamp

- » Panel Air conditioner

- » Mounting pad

MCV 400 – AMS

Details :

- » Table longitudinal travel ( X - Axis) mm 600

- » Table cross travel ( Y - Axis) mm 450

- » Headstock travel ( Z - Axis) mm 500

- » Spindle nose face to table top mm 175-675

- » Table height from floor mm 925

- » LM guideways for all three axes

- » Rigid structure

- » 20 tool ATC

- » 30m/min rapid rate for all 3 axes

- » Ideal for any machine shop

- » Value for Money. Maximum ROI

- » Ergonomically designed structure for outstanding dynamic